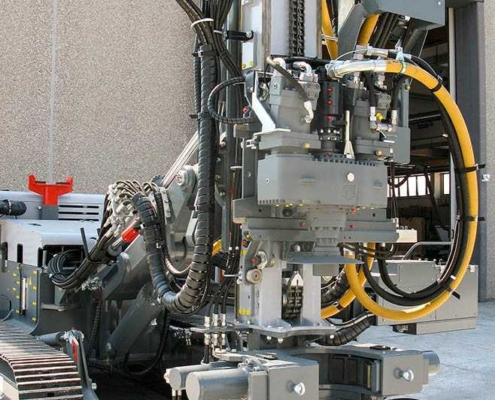

The Casagrande C6 is the history of foundations with over 3000 units produced from 1978 and the new C6-2 represents the joint venture between over 50 years of Casagrande’s experience in the fi eld of drilling, together with the innovation a feature, which characterized the long history of company’s successes.

The new Casagrande drill rig C6-2 has been designed and manufactured with increased stability and power to tackle the larger projects in the field of foundation and is suited for constructing anchors and micropiles and is particularly suited to jet-grouting.

Thanks to a new joints system, the C6-2 is a fast and rapid machine to operate, easy to use (user-friendly). Total fl exibility is the key word. The new joints system of the C6XP2 allows reaching the most extreme spots.

The SPM – Smart Power Management – and the full load sensing hydraulic system allow an intelligent engine power management to improve performance of the machinery and reduce fuel consumption. Available in hydraulic and full radio-controlled version, the new C6XP2 is designed thinking of the operator